What is Personal Protective Equipment ?

The PPE can act as a barrier between the man and hazard and to save from the injury.

There are certain operations or accidental situations where engineering controls are less possible and PPE becomes necessary.

Personal Protective Equipment (PPE) includes protective gear for the eyes, head, ears, hands, respiratory system, body, and feet. It is used to safeguard individuals from potential injuries and infections while reducing exposure to chemical, biological, and physical hazards.

PPE acts as the last line of defense when other safety measures, such as engineering and administrative controls, are not enough to fully mitigate risks.

Categories Of PPE :

Based on the nature of hazard PPE’s are divided i two categories :

01. Non-Respiratory PPE

02. Respiratory PPE

01. Non Respiratory PPE :

Example : Safety Helmet, Safety Shoes, Ear Plug, Hand Gloves, Full Body Harness, Goggles

02. Respiratory PPE :

Example : SCBA, Cartridge Mask, Dust Mask, Air Line Respirator

Why Personal Protective Equipment are important ?

PPE (Personal Protective Equipment) is important because it helps keep workers safe from dangers that could lead to injury or illness. In many jobs, there are risks that cannot be fully removed by other safety measures, so PPE is used as the last layer of protection. Here’s why PPE matters:

- PPE (Personal Protective Equipment) is important because it helps keep workers safe from dangers that could lead to injury or illness. In many jobs, there are risks that cannot be fully removed by other safety measures, so PPE is used as the last layer of protection. Here’s why PPE matters:

PPE reduces the chance of physical injuries like cuts, burns, or falls by acting as a barrier between the worker and hazards.

It protects workers from harmful things like chemicals, toxic fumes, or germs that could cause long-term health problems.

In places like hospitals, PPE such as gloves and masks help stop the spread of infections, keeping both workers and the public safe.

Many industries are required by law to use PPE. Following these rules helps businesses avoid fines and ensures safety standards are met.

When workers feel safe, they can focus better on their work, leading to improved job performance and satisfaction.

Indian Standard Code of personal protective equipment :

Head Protection :

- Helmets for industrial use: IS 2925

- Helmets for two-wheelers: IS 4151

- Non-metal helmets for police: IS 9562

- Miners’ cap lamps: IS 5679

- Wooden head form for testing helmets: IS 7692

Eyes and Face Protection :

- Selection guide for eye, face, and ear protection: IS 8520, IS 8521

- Welding protection: IS 1179

- Eye protectors and filters: IS 5983

- Safety glass: IS 2553

- Eye and face showers: IS 10592

Ear Protection :

- Selection guide for ear protection: IS 8520

- Ear protectors: IS 9167

- Earmuffs and testing methods: IS 6229

Hand Protection :

- Selection guide for gloves: IS 8807

- Leather gloves, gauntlets, and mittens: IS 2573, IS 6994

- Rubber gloves for electrical use: IS 4770

- Surgical gloves: IS 4148

Feet and Legs Protection :

- Footwear selection guide: IS 6519, IS 10667

- Safety shoes, boots, and toe caps: IS 1989, IS 5852

- PVC boots: IS 12254, IS 13292, IS 13695

- Boots for mines and heavy industries: IS 13295

- Steel toe caps for footwear: IS 5852

Body Protection :

- Selection guide for body protection: IS 8519

- Fire-resistant clothing: IS 4355, IS 7612

- Leather clothing for industrial use: IS 6153

- Safety belts for linemen: IS 3521

- X-ray protective clothing: IS 7352

Respiratory (Lungs) Protection :

- Glossary of respiratory protection terms: IS 8347

- Selection and use of respirators: IS 9623

- Colour identification of air purifying canisters: IS 8318

- Chemical cartridge respirators: IS 8522

- Gas masks and particulate filters: IS 8523, IS 9473

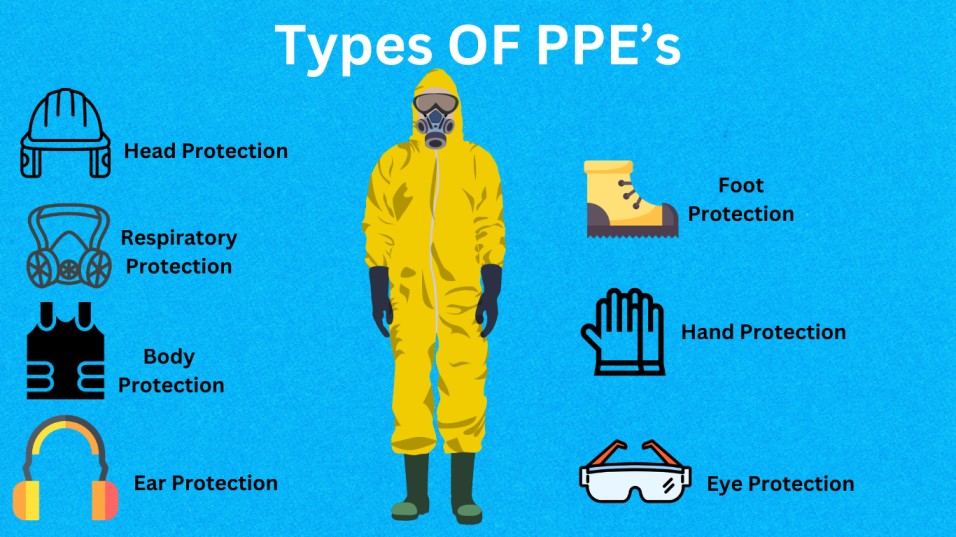

Personal Protective Equipment’s Types :

There are total 7 type of PPE Availed :

01. Face And Eye Protection

02. Respiratory Protection

03. Head Protection

04. Body Protection

05. Hand And Arm Protection

06. Foot Protection

07. Ear Protection

01. Face And Eye Protection :

Eye injuries can happen due to various hazards like dust, flying particles, chemicals, heat, and harmful radiation. These injuries can be caused by mechanical, chemical, thermal, and radiation risks. To protect the eyes, people use different types of safety equipment, such as:

- Spectacle-type Goggles : Protect against flying bodies (dust, metal clip ) etc.

- Panorama Goggles : Oil and paints splashes and dust against protect our eyes.

- Leather-mask Goggles : Protect against fumes, dust, foreign bodies.

- Chemical Goggle : Chemical and toxic dust against protect.

- Gas-tight goggles : Protect against Irritating fumes, vapour or gases.

- Welding googles : Protect against Gas Welding/ Cutting Flames & sparks.

- Welding Shields : Protect against Arc Welding / Cutting flames and sparks.

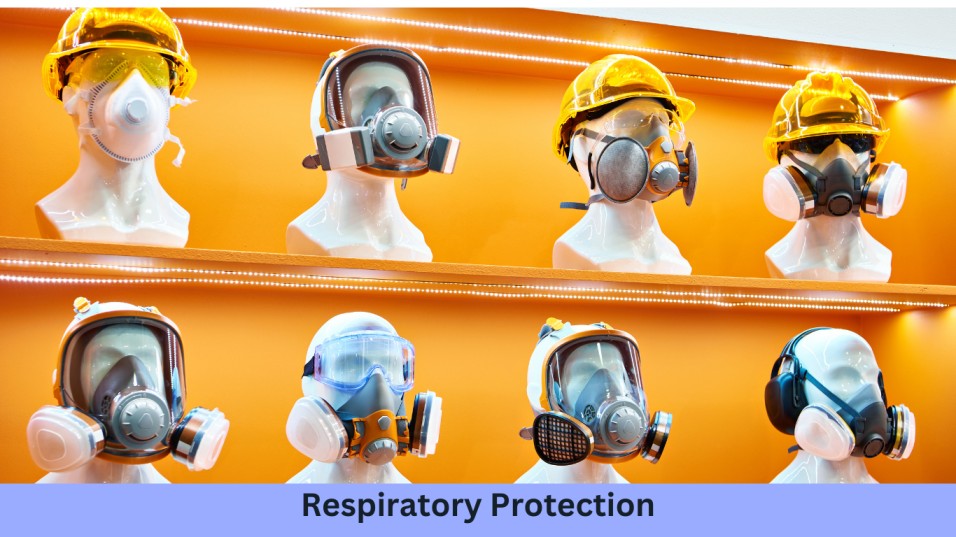

Respiratory Protection :

Respiratory protection involves using specific equipment to safeguard the lungs and respiratory system from dangerous substances in the air. These dangers may include dust, fumes, gases, smoke, or airborne chemicals that can lead to health issues or breathing difficulties.

The OSHA Respiratory Protection Standard (29 CFR 1910.1-34) lists seven key elements that

every respiratory protection program should contain.

Types of respiratory protection include :

- Dust Masks : Protect against dust, pollen, and other small particles.

- Respirators with Cartridges : Provide protection from toxic gases and chemicals.

- Self-Contained Breathing Apparatus (SCBA) : Used in environments with very low oxygen or highly dangerous gases.

- Gas Masks : Provide full-face protection against chemical and biological agents.

Head Protection :

Head protectors are hard hats, caps and helmets made of aluminium, PVC fibre glass, laminated

plastic or vulcanised fibre. They may be fitted with brackets for fixing welding masks, protective face screen or a lamp.

Safety Helmet (Hard hat) : Falling objects, hitting against obstructions such as low ceilings, beams, scaffold members etc.

Generally made of aluminium alloy, PVC, fibre- glass, or vulcanized fibre. Saddle (geodetic strap suspension) inside to dissipate impact pressure over wide area of head and to provide

clearance between the head and the shell of helmet.

Welder’s Cap : Falling welding spatters from above. Made of leather with cloth lining inside.

Crash Helmet : Skull injuries in road accidents. Usually fibre / plastic material with saddle inside, without peak or rim and with chin strap. Covers forehead, temples and lower portion of head (above neck).

Body Protection:

In various industries and hazardous environments, protecting the body from potential risks is essential. Different types of body protection gear are available to safeguard workers from heat, chemicals, electrical hazards, and physical injuries. These include:

- Asbestos combination suit: Includes asbestos jackets, hoods, clogs, boots, gloves, mittens, aprons, spats, and leggings, all designed to protect from high temperatures and heat exposure.

- Furnace mask: For furnace operations, providing protection against intense heat.

- Rubber aprons with hood: Combined protection for hazardous tasks.

- Low-weight rubber-coated fabric suit and low-weight PVC-coated fabric suit: These suits offer flexibility and protection from chemical exposure.

- Heavy-duty PVC suit or rubber-coated fabric suit: Used in demanding industrial tasks.

- PVC or rubber-coated aprons with sleeves: Full arm and body protection during tasks involving hazardous materials.

- Sand or shot blast helmet: Protects the head and face during blasting operations.

- Rubber mat for electrical purposes: Provides safety when working with electrical hazards.

- Vulcanised fibre face mask: Ideal for protecting against radiant heat.

- PVC splash-proof coats, PVC hoods with ventilators, and PVC pressure suits: These items shield workers from liquid splashes and harmful substances.

- Boiler suits, overalls, coat-pants, and hoods: Made from PVC or rubber-coated fabrics, these provide full coverage for industrial work.

Special work clothing, such as leather or wool, asbestos or aluminised clothing, and flame-retardant or fireproof suits, is essential for specific high-risk tasks, offering enhanced protection.

Safety Belts:

Safety belts and harnesses are crucial for workers operating at heights or in confined spaces. These include:

- Linemen’s leather belts, safety straps, and man-hoisting leather belts: Offer secure positioning and protection when working at heights.

- Nylon safety belts: Lightweight and durable, suitable for various industries.

- Quick-on coverall harness and suspension harnesses: Provide full-body support during fall protection.

- Wrist rescue systems and descent systems: Assist in safe rescues and controlled descents.

- Total encapsulating suit harness: Protects the entire body in hazardous environments.

- Linemen’s belts, structural steelworker belts, and derrick worker’s belts: Ensure secure working conditions in demanding tasks.

- Shock-absorbing lanyards and retractable lanyards: Help reduce the impact of falls.

- Retractable lifelines and winches: Used for secure height operations and rescues.

- Rope grabs, horizontal lifeline systems, and rail slider anchorage connectors: Provide secure attachment points for safe movement and positioning.

- Safehold confined space positioning equipment or system: Ensures safe access and work in confined spaces.

Skin Protection:

The skin acts as the body’s first line of defense against various hazards, making its protection vital. Wearing appropriate protective clothing ensures that workers are shielded from exposure to harmful substances, physical injuries, and environmental dangers, maintaining overall safety.

Hand And Arm Protection :

To protect hands and arms, workers should use appropriate safety equipment when handling materials with sharp edges, hot or molten metals, chemicals, and corrosive substances.

The types of protective gear that can be used include gauntlet gloves, wrist gloves, mittens, hand pads, thumb and finger guards, and sleeves.

However, gloves, hand leathers, arm protectors, and similar items should not be worn near moving machinery or machine parts to avoid the risk of entanglement.

Foot Protection :

Some typical risks are handling of heavy materials, caustic and corrosive liquids, wet conditions, molten metals, etc. Common foot and leg protective equipment are safety shoes or boots,

leggings and footguards.

Safety shoes/boots may be conductive, non conductive or spark resistant.

Rubber boots are useful to work in wet conditions, steel toe boots against impact and puncture resistant soles to walk on surfaces having nails, sharp objects etc.

Electricians need insulated shoes with non-metal parts.

Safety Shoes & Boots Types :

Safety leather boots

Asbestos clogs or boots with leather soles

Asbestos long boots

Rubber gum boots

Leather ammunition boots

Leather/rubber sole shoes with or without steel toe

Electric shock-proof shoes tested to 11 KV

Welder’s safety boots

Miner’s boots & Hunter’s shoes

Ear Protection :

Noise level can be measured by a noise average meter or a noise dose meter.

Noise level above 90 dBA is hazardous for an exposure more than 8 hrs/day or 48 hrs/week.

It may cause deafness, fatigue, loss of efficiency, irritation and also loss of hearing.

Ear plugs or Ear muffs reduce to @ 25 to 40dBA.

Ear plug is made of plastic, rubber or polyurethane foam.

Ear muffs covers external ear and provides better attenuation than ear plug.

Many Type Of Ear Plug Available :

Ear muffs, or cups

Plugs or inserts

Dielectric ear muff

Formable (disposable) aural inserts

Full enclosure (e.g. astronaut)

Superaural or canal cap

Conclusion :

Personal Protective Equipment (PPE) is important for keeping workers safe. Choosing the right PPE and using it properly helps protect people from injuries and sicknesses at work. With the right equipment and care, both workers and companies can lower the risk of accidents and health problems caused by workplace dangers.

Read More : Carbon Disulfide