Hydro Test

Introduction to Hydro Testing

A hydro test is a commissioning activity after the completion of piping, vessel, and reactor construction in the industry.

Hydrostatic pressure testing is commonly known as a hydro test.

What is Hydro Testing

The hydro test process is used to verify the integrity, durability, and strength of piping, vessels, reactors, and their jackets, heat exchangers, boilers, etc., by subjecting them to water pressure.

Why is Hydro Testing Important

- Detect leakage, cracks, damage, and corrosion in pipelines, tanks, vessels, and reactors.

- Prevent catastrophic failure that can lead to injuries, property damage, and environmental damage.

- Ensure structural integrity for working pressure and prevent failure in normal conditions.

Hydro Test Equipment & Tools

- Pressure pumps

- Pressure gauges

- Test recorder

- Manifold hoses, fittings, and valves

- Safety valve

Hydro Testing used

- Pipeline and piping systems are used in oil, gas, water treatment plants, power generation, and the pharmaceutical, chemical, and petrochemical industries.

- Boiler and pressure vessel

- Gas cylinder and fire extinguisher

- Storage tank and heat exchanger

Hydro Test Process

- Hydro test of pressure vessels

- Hydro test of pipelines

- Hydro test of heat exchanger

- Hydro test of reactor jackets

1. Hydro test of pressure vessels

Document Verification:

- Review design drawings and confirm vessel design pressure.

- Ensure the hydro test pressure is calculated as per the applicable ASME code.

- Ensure all calibration certificates for gauges and test pumps are ok.

Vessel Inspection & Physical Preparation:

- Ensure all welding, including nozzles and manways, is complete and acceptable.

- Install blinds/gaskets at all open flanges.

- Ensure proper vents at high points and drains at low points.

- The vessel should be fully supported and stable.

- Ensure the vessel is free of debris, loose parts, and foreign material.

- Remove or protect pressure gauges, transmitters, relief valves, etc.

1. Installation of Test Equipment

- Two pressure gauge fittings at least.

- Provide a pressure relief valve to avoid pressurization.

- Install a vent line for air release during water filling.

2. Safety measures

- PTW provides for a hydrotest.

- Conduct toolbox talks with all workers involved in hydrotests.

- Use appropriate PPE.

- Areas are barricaded with warning labels.

3. Before hydrotest preparation

- Review design drawings and confirm vessel design pressure.

- Ensure the hydro test pressure is calculated as per the applicable ASME code.

- Verify all calibration certificates for test gauges and test pumps are valid.

- Ensure all welding, including nozzles and manways, is complete and acceptable.

- Install blinds/gaskets at all open flanges.

- Ensure proper vents at high points and drains at low points.

- The vessel should be fully supported and stable.

- Ensure the vessel is free of debris, loose parts, and foreign material.

- Remove or protect pressure gauges, transmitters, relief valves, etc.

- At least install pressure gauges.

- Provide a relief valve or pressure release system to avoid overpressurization.

- Set up a test pump with a pressure rating above the test pressure.

- Install vent lines for air release during water filling.

- Ensure the permit to work (PTW) for the hydro test is approved and signed.

- Barricade the area and place warning signage (Hydrotest in Progress).

- Conduct a Toolbox Talk with the testing worker.

- Ensure all team members wear appropriate PPE.

- Establish clear communication channels.

- Keep the first aid kit and emergency equipment ready.

4. Pressure vessel hydrotest procedure after preparation

- Start the test pump slowly and increase pressure in stages.

- vessel filled to 25% → 50% → 75% → 100% of test pressure.

- Pause briefly at each stage to inspect for leaks.

- Monitor

- Pressure stability on the gauge.

- No visible leakage (sweating, dripping, or jetting).

- No bulging, distortion, or deformation of the vessel shell or welds.

5. Inspection During Pressure Holding

- The pressure should not drop during the holding period.

- Conduct a visual inspection of all welds, joints, and nozzles.

- No cracks, leakage, or sweating at any weld or joint.

- No signs of material deformation.

- An inspector or third-party inspector (TPI) should witness the test and sign off.

- Once test pressure is reached, hold pressure for the required duration of 30-45 min.

2. Hydrotest of pipelines

A hydro test is a pressure test performed on a pipeline using water as the testing medium. The hydro test’s main objective is to verify the leak test, strength, and integrity of pipelines before use, repair, and new line erection work.

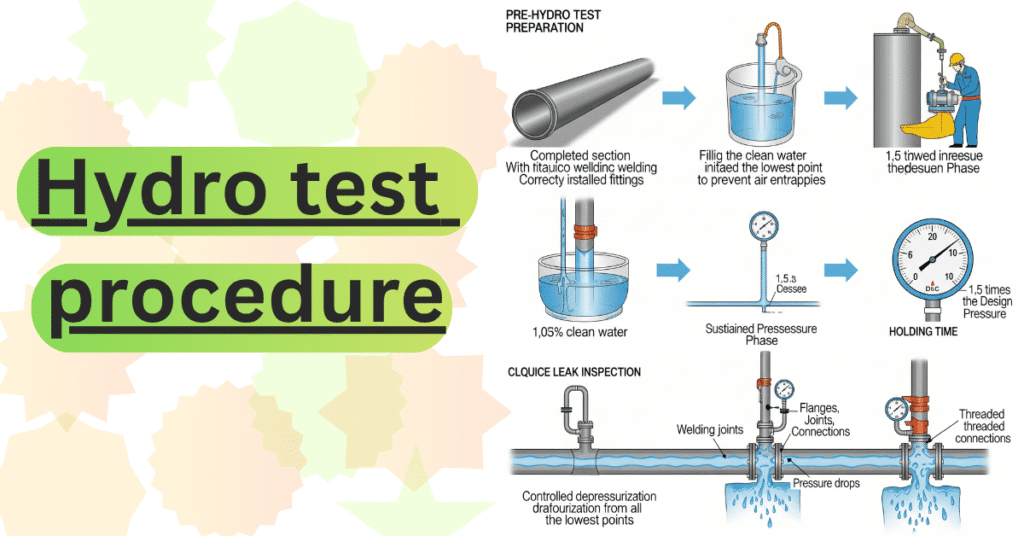

Pipeline Hydro test procedure

1. Pre-hydro test preparation

- All welding work should be complete.

- The pipeline should be fitted.

- Proper pipeline test drain point, vent, and blind fitting properly.

- Checking the lowest point and highest point for hydro test in the pipeline valve.

2. Filling water in the pipeline

- Use clean water free from contaminants.

- Fill water from the pipeline’s lowest point to avoid air locks.

- Keep open until water comes out of the vent valve, then close after the water comes out of the vent valve.

3. Pressurization

- Slowly increase the pressure in the pipe with the hydro test pump.

- Test pressure: 1.5 times the design pressure as per ASME Code.

4. Holding time

- Hydro Test Pressure hold from 30 min to 120 min (based on code and client requirement)

- Monitor pressure gauge and inspect it.

5. Inspection

- Check for flange leaks, joint leaks, welding leaks, threaded leaks, or pressure drops in pipelines.

6. Depressurizing/Draining

- Slowly release the water pressure so that the pipe is not hammered.

- Check that the water has drained from all the lowest points of the pipeline.

3. Hydrotest of the heat exchanger

Why heat exchanger hydro test is important

- A hydro test is conducted to verify the design pressure of the heat exchanger and determine if its design is suitable.

- Identify leaks in joints, cracks, and welding joints, and check porosity.

- Prevent catastrophic failure during operation.

- A hydro test is required for regulatory compliance (ASME, TEMA).

Heat Exchanger Hydro Test Procedure

1. Pre-test procedure

- Verify all welding, fitting, and fabrication work.

- Fit a temporary blind and close all nozzles and openings.

- Calibrated pressure gauges are installed.

- Ensure the hydro test area is barricaded and safe.

2. Filling water

- Fill the heat exchanger shell side/tube side with clean water.

- Fill water from the lowest point to avoid an airlock problem.

- Vent air is removed from the highest point to the HE.

3. Pressurization

- Once the water is filled, slowly increase the pressure with a hydro pump.

- Raise pressure to 1.3 to 1.5 times the design pressure as per the standard.

- Maintain 30 min to 120 min.

4. Inspection

- Inspect all points, all flanges, and all joints for leakages.

- Ensure no pressure drop and no leakages.

- Observe pressure.

5. Depressurization and draining

- Slowly release pressure from the drain point.

- Drain HE completely from all low points.

- Dry HE using N₂ and air.

4. Hydrotest of reactor jackets

The reactor jacket is a secondary pressure-containing shell welded around the main body of the reactor.

Objective of the hydro test of the reactor

- Check the strength of the reactor jacket

- Check for a leakage and puncture of jackets

- A hydro test is a legal requirement for pressure vessels.

Hydro test of reactor jackets procedure

1. Filling water

- Slowly filling water through the bottom drain.

- Keep the vent open to avoid an airlock.

- Keep the vent open until the water overflows from the top side.

2. Apply pressure

- Using a hydro pump through a rising pressure gradually.

- Increase 50%-75%-100%

3. Inspection

- Check flange joint leakages, punched.

- ensure no leakages and no pressure drop.

4. Depressurization and draining

- Do not open the flange under pressure.

- Gradually release pressure and water drain.

Expand Your Knowledge on [Properties of Hydrogen]

Hydro Test Pressure Calculation

1. Hydro test calculation for a pressure vessel

Hydrostatic pressure = 1.3 × MAWP (maximum allowable working pressure)

OR

Hydropstatic pressure = 1.3 × design pressure

OR

MAWP OR design pressure is not calculated when required.

HP = 1.3 × MAWP × stress value of design temp/Stress value of working temp

Test Pressure=1.3 × MAWP × St/Sd

If design temp and test temp are both the same St/Sd≈1

Sd = stress value if material design temperature

St = stress value if material test temperature

Example 1:

hydro test with the same stress design and test temperature

MAWP=10 bar

Allowable Stress at Design Temp (Sd) = 150 MPa

Allowable Stress at Test Temp (St) = 150 MPa

HydroTest Pressure=1.3 × MAWP × St/Sd

Hydrtest pressure = 1.3 × 10 × 150/150

Hydrotest pressure = 13 bar

Example 2:

Hydrotest with different allowable stress

MAWP = 500 psi

Allowable Stress at Test Temp (St) = 18,000 psi

Allowable Stress at Design Temp (Sd) = 15,000 psi

HydroTest Pressure=1.3 × MAWP × St/Sd

HydroTest Pressure=1.3 × 500 × (18000/15000)

= 1.3 × 500 × 1.2

= 780 psi

=780 × 0.07031

= 54.84 kg/cm2

2. Hydro test calculation for piping system

Hydrotest pressure = 1.5×MAWP×St/Sd

Sd = stress value if material design temperature

St = stress value if material test temperature

if design temp and test temp both are the same St/Sd≈1

Example calculation

Example 1:

Same Stress at Test & Design Temperatures

Stress Ratio = 1

Design Pressure = 20 bar

St = 150 MPa

Sd = 150 MPa

Hydrotest pressure = 1.5×MAWP×St/Sd

Hydrotest pressure = 1.5×20×1

= 30 bar

=30 bar × 1.01972

=30.59 kg/cm2

Example 2:

Different Allowable Stresses

Design Pressure = 50 bar

St = 120 MPa

Sd = 150 MPa

Hydrotest pressure = 1.5×MAWP×St/Sd

Hydrotest pressure = 1.5×50×(120/150)

= 75 × 0.8

= 60 bar

= 60 bar × 1.01972

= 61.18 kg/cm2

Hydro Test in Different Applications

- Pipelines and piping systems

- Pressure vessels and boilers

- Fire extinguishers and gas cylinders

- Storage tanks and heat exchangers

Conclusion

Hydro testing is a critical safety procedure used to verify the strength, integrity, and leak-tightness of pressure-retaining equipment such as piping systems, pressure vessels, boilers, heat exchangers, and reactors. By subjecting these components to water pressure above their design pressure, potential failures, cracks, and weaknesses are identified before actual operation. It ensures compliance with ASME and industry codes, prevents hazardous incidents, and enhances equipment reliability. Proper preparation, calibrated instruments, adherence to safety protocols, and accurate pressure calculations are essential for a successful hydro test. Ultimately, hydro testing plays a vital role in safeguarding plant operations and personnel.

Q&A

1. What is the purpose of hydro testing?

Ans:

Hydro testing verifies the strength, integrity, and leak-tightness of pressure-retaining equipment (like piping, vessels, boilers, and heat exchangers) by subjecting them to pressurized water. It helps identify any leaks, material flaws, or fabrication defects before the equipment is commissioned for service.

2. What pressure is used during a hydro test?

Ans:

Typically, the hydro test pressure is 1.3 to 1.5 times the Maximum Allowable Working Pressure (MAWP) or design pressure, depending on applicable codes such as ASME B31.3 or ASME Section VIII. The test pressure is adjusted if the allowable material stress changes between design and test temperatures.

3. How long should a hydro test pressure be held?

Ans:

The standard pressure holding time is generally 30 to 45 minutes for pressure vessels and up to 2 hours for long pipelines, or based on client specifications and applicable codes. During this time, all joints, welds, and connections are visually inspected for leaks and pressure drops.

4. Can hydro testing damage the equipment?

Ans:

Yes, if performed incorrectly (e.g., over-pressurization, rapid pressurization, trapped air), hydro testing can cause bulging, cracking, or deformation of components. This is why gradual pressurization, air removal, calibrated instruments, and trained personnel are essential.

5. Is hydro testing mandatory for all pressure equipment?

Ans:

Yes, hydro testing is mandatory before the commissioning of new pressure equipment and after major repairs or modifications, as per ASME, IBR, API, and other international standards. It is also part of periodic inspections in regulated industries like oil & gas, chemical, and power sectors.