Type OF Scrubbers

Industrial scrubbers have long been a reliable solution for purifying exhaust streams in various industrial settings. With advancements in technology, modern scrubbers have become even more efficient at removing pollutants. By selecting a scrubber with the right features, you can effectively prevent harmful pollutants from being released into the atmosphere.

What Are Industrial Scrubbers ?

Industrial facilities use specialized devices to purify their exhaust streams, removing pollutants that can harm the environment and human health. These devices, known as scrubbers, capture particulate matter and gases, ensuring that the air released into the atmosphere is clean and safe.

How to scrubber protect our environment ?

- Air Quality Improvement: Scrubbers remove particulate matter, gases, and other pollutants from the air, improving the overall air quality and reducing the negative impacts on human health and the environment.

- Prevention of Acid Rain: Scrubbers can remove sulfur dioxide and nitrogen oxides from exhaust streams, which are major contributors to acid rain. By removing these pollutants, scrubbers help prevent acid rain and its devastating effects on ecosystems.

- Reduction of Greenhouse Gas Emissions: Some scrubbers can capture and remove greenhouse gases, such as carbon dioxide and methane, which contribute to climate change.

- Protection of Waterways: Scrubbers can remove pollutants that might otherwise contaminate waterways, protecting aquatic ecosystems and preventing harm to aquatic life.

- Soil Conservation: By removing pollutants from the air, scrubbers help prevent soil contamination and degradation, which can have long-term effects on ecosystems and human health.

- Reducing Odors and Noise Pollution: Scrubbers can also remove odorous compounds and reduce noise pollution, improving the quality of life for nearby communities.

- Compliance with Environmental Regulations: By using scrubbers, industries can comply with environmental regulations and standards, reducing the risk of fines and penalties.

Scrubber are mainly two types :

01) Wet scrubber

02) Dry scrubber

Type of scrubber :

01. Spray tower

02. Venturi scrubber

03. Cyclone scrubber

04. Packed scrubber

05. Mechanical scrubber

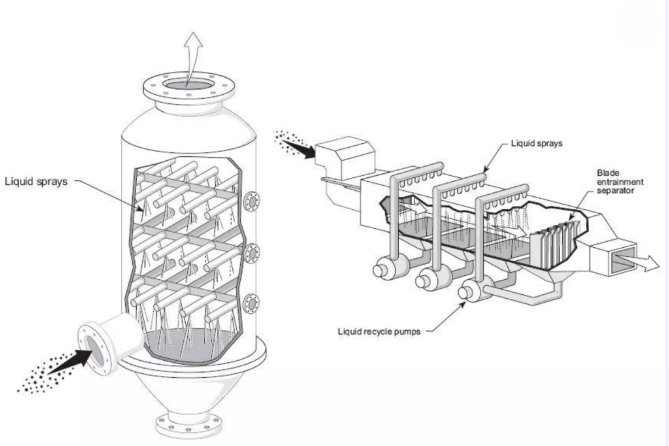

01. Spray tower :

- Low energy (pressure drop is 1.3 to 7.6 cm water) inexpensive devices

Used as pre-scrubbers for removing :-

- larger particles (of size >10-25μ)

- highly soluble gases (with 50-80% efficiency – plate towers and packed towers are superior for gas absorption removal)

- chemical reagent addition to the liquid (KMnO4 for odor removal) can also increase the efficiency

- Used to handle flows upto 50 m3/sec

Counter-current, co-current and cross-current configurations are used :-

- Cross-current configurations (horizontal spray scrubbers) can have more than one spray sections.

- For better results the liquid can flow counter-current and cleanest liquid can be sprayed in the last section.

- Counter-current configurations can have multilevel liquid spray nozzles.

- For similar collection efficiencies co-current configuration is smaller than a counter-current configuration.

- Exhaust relative velocity is higher in the counter-current configuration

Exhaust enters the bottom and moves upwards in counter- current flow configuration :-

- Exhaust gas velocity is within 0.3 to 1.2m/sec. to prevent liquid carry over.

- Liquid at pressure is 10-400 psig is sprayed through nozzles downwards into the spray tower.

- Produces droplets of size 500 to 1000μ (venturis produce 10 to 50μ size droplets).

- injection of liquid at 300 to 450 psig pressure creates fog like droplets.

- Liquid to gas ratios employed are 0.7 to 2.7 L/m3.

- Decreasing liquid droplet size and increasing liquid to gas ratio can increase the absorption removal.

- Liquid droplets after falling short distance tend to agglomerate into bigger drops or hit walls and comedown affecting efficiency.

- Completely open design – have least scale buildup and plugging problems.

- Nozzle plugging or eroding can occur specially with recycled liquid.

Baffled Spray Scrubbers :-

Similar to spray towers both in design and operation :

- In addition to spray nozzles, baffles (that allow further atomizing of liquid) are added to boost treatment.

- Used mostly as pre-cleaners for the removal of >10µ size particles.

- Not specifically used for the removal of gases.

- Pressure drop is 2.5 to 7.5 cm water.

- Liquid to gas ratio is 0.13 L/m3.

- Liquid inlet pressure is <15 psig.

- Maintenance problems are the least – solids buildup on baffles can occur.

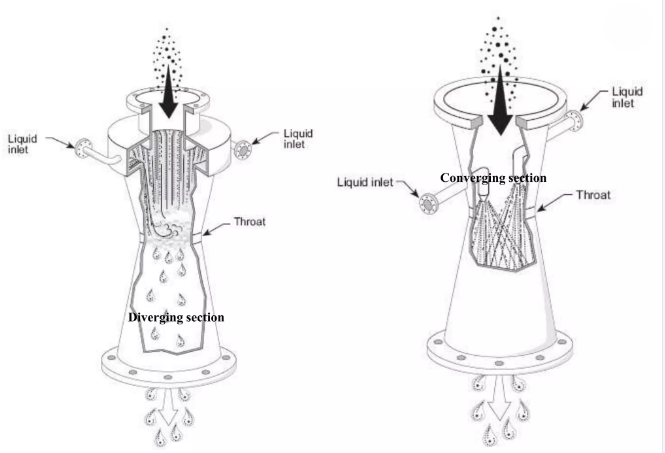

02. Venturi scrubber :

A gas phase contact scrubber used to collect both particles and gaseous pollutants.

Has 3 sections : converging, throat and diverging section :

Exhaust stream is forced to move through throat at extremely high velocity (30-120 m/sec.).

- Liquid is introduced into the throat either at the throat or at the entrance of the converging section.

- At the throat the liquid is sheared from walls and atomized into very small droplets.

- Gas exiting the diverging section is forced to slow down for removing the liquid droplets.

Entrainment separator (cyclonic or mesh pad or blade separator) is used for the removal of entrained liquid droplets.

– Cyclonic separator when used is connected to the venturi usually by a flooded elbow.

Non-wetted (dry throat) approach venturi :-

- liquid is introduced at the throat.

- in case of high temperature exhaust caking of throat can occur.

- appropriate for cool moist exhaust.

Venturi with wetted approach :-

- liquid is introduced at the entrance of the converging section.

- Venturi with round throat can not handle larger flows (> 88000 m3/hr) – Venturi with long, narrow, rectangular throat can be used.

For handling variable gas flows adjustable throat venturis (with varying throat areas) are used :-

- Venturi with a plunger or adjustable disc moving up and down the throat (decreasing and increasing annular opening of the throat).

- Rectangular throat venturis with movable plates that decrease or increase throat area.

- Venturi rod or rod deck scrubber – a number of pipes parallel to each other in the exhaust flow path create a series of rectangular throat openings.

Highest particle collection efficiency (90-99%) among scrubbers :-

- Operated at pressure drops of the throat is 30 to 120 m/S) 5 to 100 inches (gas velocity in the throat is 30 to 120 m/s).

- Increasing pressure drop across increases efficiency.

- Liquid to gas ratios employed are 0.4 to 1.3 L/m³.

- Higher ratios do not significantly increase efficiency and lower ratios may not sufficiently wet the throat.

Removal efficiency for gases is 30-60% :-

- Very short gas-liquid contact time limit gas absorption.

- Efficient removal occurs if the gas is chemically reactive with or it is highly soluble in the liquid.

- Lower exhaust velocities and higher liquid to gas ratios can enhance the removal efficiencies.

- Liquid to gas ratios of 2.7 to 5.3 L/m³

Wear or abrasion of the scrubber shell is the primary maintenance problem with venturis :-

- Lining the throat with silicon carbide or using replaceable liner can minimize the problem.

- A pre-cleaner through removing larger particles can also reduce abrasion problem.

- Flooded elbow at the bottom of the scrubber can reduce abrasion downstream to the throat.

Method of liquid injection (spray nozzles/weirs) can also cause problems :-

- Spray nozzles can clog specially with recirculated liquid Nozzles holes twice the size of openings of the strainers used in the liquid recycle line can minimize clogging.

Scrubber working principle :-

Impingement and interception

Less than 1-2 μrange particulates are collected

Advantage :-

Simultaneously remove particulates and gaseous pollutants.

Hot gases can be cooled down.

Corrosive Gases can be recovered and neutralize.

Disadvantage :-

Lot of waste waters produced.

Poses freezing problem in cold countries.

Maintenance cost is high when corrosive material are collected.

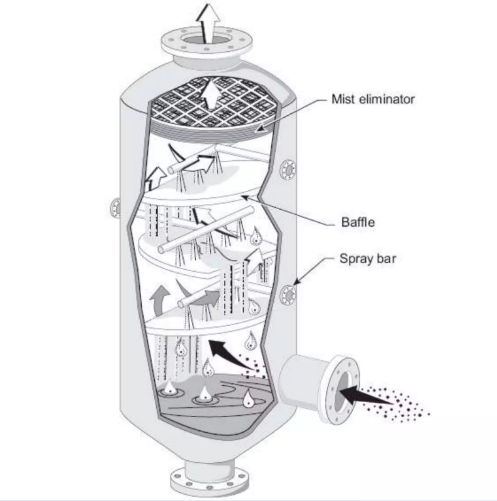

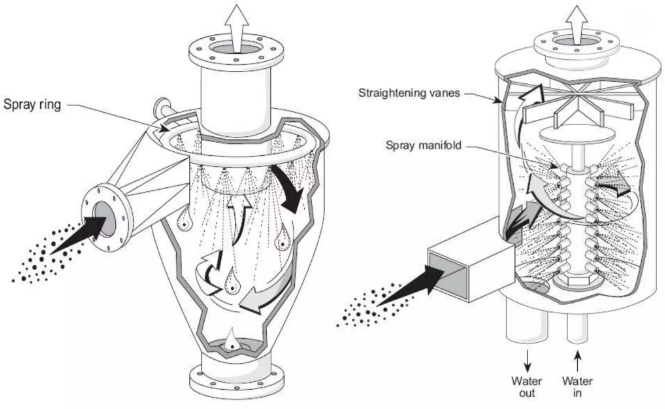

03. Cyclone scrubber :

Low to medium energy devices (pressure drop is 4 to 25 cm of water) :-

- Uses the features of both a dry cyclone and spray tower for collecting particulate matter.

- More efficient than spray towers but less efficient than venturi scrubbers.

- Particles >5 µ are removed with >90% efficiency.

- Particle velocity is 60-180 m/sec. comparable to venturis (in spray towers it is 0.6 to 1.5 m/sec.

- Turbulence level is much lesser than that generated in a venturi.

- Less efficient in removing gaseous pollutants and not chosen for gaseous pollutant removal.

Include Irrigated cyclones and Cyclonic spray scrubbers :-

01) Irrigated cyclone :

Exhaust enter tangentially near the top into water sprays and swirls downward, then change direction return upward in a tighter spiral

02) Cyclonic spray scrubber :

- Exhaust enters the chamber tangentially near the bottom, swirl through the chamber moves upwards and exit from top

- Liquid is sprayed from nozzles on a central post and directed

- toward the chamber walls

- Straightening vanes are provided at the top of the chamber

- Can also act as entrainment separators

Nozzle plugging and corrosion or erosion side walls are the maintenance problems :-

Better install the nozzles in a way for ease of access for maintenance.

Abrasion resistant materials may be used to protect the cyclone body.

- Liquid to gas ratio employed is 0.3 to 1.3 L/m3

- Liquid inlet pressure is 280 to 2800 kPa

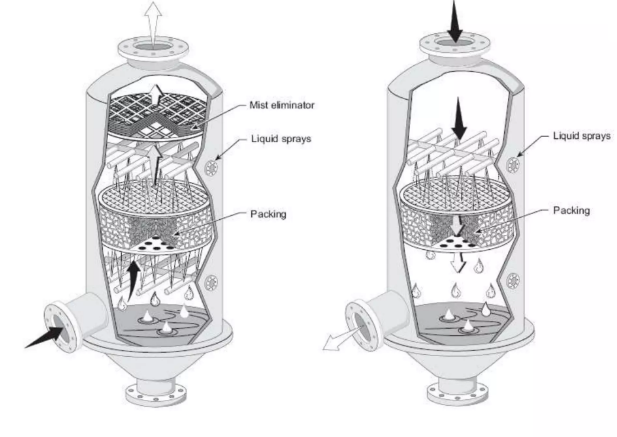

04) Packed scrubber :

Medium energy scrubbers used for gas absorption :-

- Particles are also removed, but submicron particles not efficiently.

- Both liquid phase and gas phase provide the energy needed for the scrubbing.

Used for handling smaller flows and easy to handle gases :-

- For larger flows and difficult gases plate towers are preferred.

- Cheaper but weight is more than that of plate tower.

- Packing material supported over trays is sprayed with liquid to form liquid film coat.

- Exhaust is passed through packing for contact with liquid.

Absorption removal is enhanced by :-

- Liquid film surface

- Turbulent contact between the liquid and gas

- Contact time

- Solubility of the gaseous pollutants

Higher gas velocity through packing ensures good mixing but can cause flooding of packing

Increasing liquid injection increases absorption efficiency but can cause flooding

Common used configurations include counter-current, co- current and cross-flow

Counter-current flow configuration :-

- Liquid is introduced at the top of packing by sprays/weirs

- Exhaust is entered at bottom and flown through upward

Co-current flow configuration :-

- Both exhaust and liquid enter at top and move downward

- Can operate at higher liquid & gas flow rates without flooding

- Removal efficiencies are limited

- For similar flows and absorption efficiencies, diameter of the tower is relatively smaller and pressure drop is lower

Cross flow configuration :-

- Exhaust moves horizontally while liquid moves vertically.

- liquid sprays at the face of packing on the inlet side may also be used.

- packing can be slanted in the direction of incoming exhaust for ensuring complete wetting of packing.

- can include more than one sections.

- liquid flow rate can be higher in the front section for particulate washout.

- last section can be left dry to act as entrainment separator.

- considered as better for handling exhausts with high particulate concentration.

- can be designed to have lower pressure drop.

- Fiber bed scrubber with cross flow scheme.

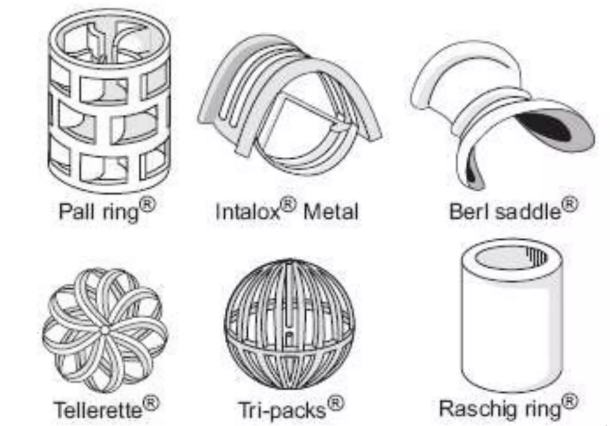

Material used as packing include :-

- stoneware, porcelain, metal, high density thermoplastics (polyethylene and polypropylene), etc.

- Dimensions can be of 0.6 to 10 cm in size.

- Smaller size offers larger specific surface area but increases pressure drop.

Shapes of packing material used :-

- Raschig rings (5 cm)

- Tellerette packing (2.5 cm)

- Tripacks

- Pall rings

- Intelox metal

- Bari saddle

Factors influencing selection of packing material include nature of contaminants, geometric mode of contact, size of the absorber, and scrubbing objectives.

Cost, pressure drop, corrosion resistance, specific area, structural strength, weight, design flexibility, etc., also influence.

Packing can be either random or stacking systematically :-

- Random packing provides higher specific surface area but cause higher pressure drop and poor liquid distribution.

- Stacked packing provides better liquid distribution but installation costs are higher.

Proper design of support trays can ensure uniform distribution of exhaust through the packed bed

Metals plates or grids used to support the packing also act as distribution baffles

Liquid should be distributed the entire the top surface of the packed bed

Channeling of the quid should be avoided

Liquid tend to flow towards tower walls and result in short circuiting

Require redirecting from the tower walls back to the center of the packed column by liquid redistributors placed at intervals of <3 m or at 5 tower diameters from the top

Liquid distribution is by weirs, tubes or spray nozzles Distribution Weirs :-

- Do not plug and can handle dirty liquids but require leveling.

- Can be easily inspected and maintained.

Perforated tubes :-

- Can be buried within the packing – allows the packing above the perforated tube to act as entrainment separator.

- Avoids liquid blowing against the side walls of the tower.

- Tubes (and perforations) can clog and knowing it is difficult.

Spray nozzles :-

- Nozzle clogging and erosion can be a problem

- Use of fewer relatively large nozzles can avoid the clogging

- Can be easily inspected

- pressure drop is the highest among the three

-

Type Of Scrubbers

Buildup of solids in the packing is a serious problem :-

- Particulate matter tend to get removed and accumulate in the packing-pre-cleaning spray can reduce the solids buildup.

- Buildup could also result from chemical reactions between the liquid and absorbed gases.

- Liquid draining through the packing carry the collected particles and plug the void spaces.

- Tower internals are not easily accessible and cleaning requires shutting the system and removing, cleaning and reinstalling the packing.

Maintaining proper liquid and exhaust flows is needed – increasing any of the two can result in flooding :-

- Flooded packing result in higher pressure drop, pulsating air flow and dramatically reduced efficiencies.

- Optimal operating flow rates should be 60-75% of the flooding flow.

Lower gas flow rates can result in gas channeling.

Liquid to gas ratio employed is 0.13 to 2.0 L/m3 and liquid inlet pressure is 5-15 pig.

Pressure drop is 1.7 to 5 cm water per foot or 2 to 8.5 cm of water per meter of installed packing and 5 to 22 cm of water across the packed tower.

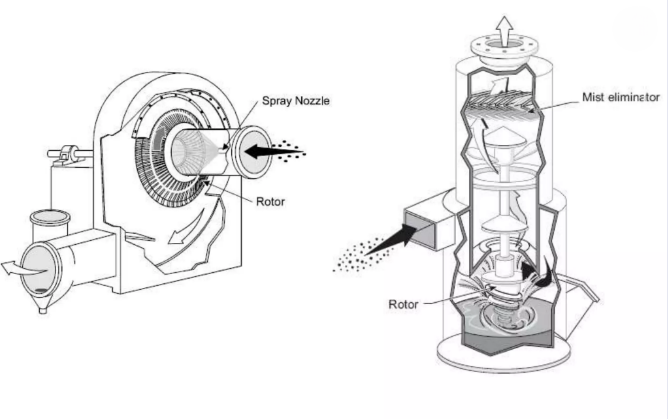

05. Mechanical scrubber :

Motors are used to supply the energy needed for scrubbing More compact but have higher overall power requirement

Capable of high particle collection efficiencies and can

remove particles of >1µ size

Generally not used for gas absorption

Operate at low liquid to gas ratio :-

- 0.07 to 0.2 L/m3 for centrifugal fan scrubbers

- 0.5 to 0.7 L/m3 for spray rotor scrubbers

Because of moving parts maintenance problems are high :-

- Moving parts are susceptible to corrosion and fouling

- Rotating parts are subject to vibrations – induced fatigue or wear cause them to become unbalanced

- Not used with corrosive or sticky materials

Centrifugal fan scrubbers :

- Serve as both air movers and particle collection devices.

- Water is sprayed (at 20-60 psig pressure) on blades to form droplets and to impart centrifugal motion to droplets.

- Rotating blades force both liquid and particles off the blades towards the walls of the casing.

- Extra power consumption equivalent to 10.2 to 15.2 cm water occurs from use as particulate collection devices.

Induced spray scrubbers :-

- Vertical whirling rotors submerged in a liquid pool are used to produce fine droplet sprays.

- Exhaust is forced to move through the spray.

- Pressure drop across the device is 10-20 cm water.

Read More : NFPA diamond

Conclusion :

An Industrial scrubber is a device that removes pollutants and contaminants from industrial exhaust or flue gas streams. It uses a chemical solution or dry sorbent to absorb or neutralize pollutants, allowing clean air to be released. Scrubbers come in various types, including wet, dry, electrostatic, venturi, and packed tower scrubbers. They consist of an inlet, scrubbing chamber, outlet, and control system. Scrubbers help companies meet air pollution regulations, improve public health, and protect the environment. They are essential in various industries, including food, electroplating, acid plants, fertilizer plants, steel mills, and asphalt plants.