Unsafe Act And Unsafe Condition

Every workplace must consider the core aspect that deals with protection of workers, assets, and operation and is referred to as safety.

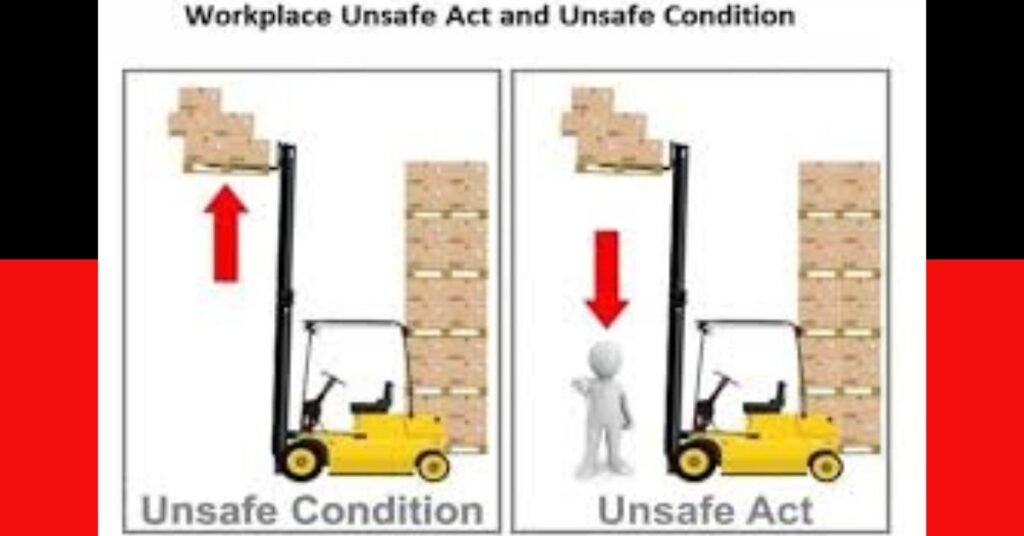

Among various significant words of the safety word, which we have learned of in our work, Unsafe Act And Unsafe Condition, Even though they may look the same, there’s a difference in meaning that differentiates one from the other while providing value in an additional manner to the hazards and risks present in the workplace.

Therefore, this is crucial for the effective building of the safety plan towards developing safety culture within the workplace as well as for accidents reduction.

What is an Unsafe Act?

An unsafe act is a decision or behavior by an individual that deviates from standard safety practices or procedures, creating a risk of injury or damage. It is a human action that either intentionally or unintentionally compromises safety. Such acts usually happen due to time pressure, complacency, lack of awareness, or poor training.

Examples of unsafe acts include :

1. Failure to Wear Personal Protective Equipment : Working without wearing a helmet, gloves, or protective eyes as demanded.

2. Safety Shortcuts : Omission of some of the steps in the safety process, ignoring safety barricades, or ignoring the warning signs and signals.

3. Inappropriate Application of Machines or Tools : Performing improperly or using them for work other than that for which they were designed.

4. Short hands : Failure to follow routine practice by reducing efforts to get more time may mean attempting to lift loads beyond your ability or neglecting equipment lockage.

5. Horseplay : Distracting others, for instance, or acting imprudently in potentially dangerous situations.

Unsafe acts are behavioral and may therefore be spontaneous and consequently even harder to predict than the unsafe conditions. They will also be controlled by appropriate training and awareness programs combined with a work environment ingrained with safety consciousness as well.

What is an Unsafe Condition?

Poorly maintained conditions are environmental, physical, or mechanical risks with a higher probability of leading to accidents and/or injuries. Although unsafe acts pertain to specific behavioral practices, unsafe conditions, as a rule, are attributed to poor maintenance, poorly designed workplaces, or other environment-related factors. They represent identifiable hazards that exist unless intervened upon, and the hazard is present regardless of any action taken by a person.

Examples include:

1. Long-term Non maintenance of Equipment

Lack of guarding on machinery or damage to some parts.

2. Poor Lighting or Ventilation

Poor lighting cannot identify potential hazards, and inadequate ventilation may lead to toxic fumes.

3. Wet or Cluttered Walkways

Walkways littered with tools or wet floors, leading to slips, trips, and falls.

4. Exposure to Harmful Chemicals or Agents

Lack of proper labeling or chemicals placed in areas where they may spill.

5. Poorly Conducted or Leaking Electrical Wiring

Leakage that causes electrical shocks or fires.

Most unsafe conditions are usually treated through regular inspections, proper maintenance, and adherence to occupational safety standards. Unlike unsafe acts, unsafe conditions can be more predictable and consequently dealt with by safety measures on the physical dimension as well as through preventive maintenance.

Major Differences Between Unsafe Act and Unsafe Condition :

1. Nature of Hazard

Unsafe Acts : Behavioral risks brought about by the actions of people, either intentionally or unintentionally.

Unsafe Conditions : Physical or environmental risks that are available in the workplace.

2. Cause

Unsafe Acts : Usually caused by human error, lack of training, or intentional neglect of safety practices.

Unsafe Conditions : Often due to poor maintenance, insufficient safety measures, or wrong workplace design.

3. Detectability

Unsafe Acts : Less detectable because it depends on human actions that change at any moment.

Unsafe Conditions : Can be easily identified in the course of safety inspection, audit, or through routine maintenance.

4. Responsibility for Prevention

Unsafe Acts : Primarily the responsibility of workers to follow procedures and for management to enforce adherence to safety policies.

Unsafe Conditions : Generally the responsibility of employers and safety officers to maintain a safe environment.

5. Occurrence and Duration

Unsafe Acts : Occur sporadically and typically are momentary actions.

Unsafe Conditions : Remain latent and uncontrolled until they are identified and corrected, and always pose a potential threat in the workplace.

Contributing Factors to Unsafe Act and Unsafe Condition :

Causes Of Unsafe Acts :

Training and Awareness

The workers do not know the danger posed by a particular job or do not know the proper procedure.

Overpressure and Complacency

Urgency to meet target dates of certain jobs might make employees avoid safety measures or compromise on safety

Overconfidence

Over-confident or experienced employees feel that they are perfectly safe and do not need avoidance measures because of their experience.

Inadequate Leadership

Lack of observation will create unruly or improper behavior.

Poor Communication

Uncommunicated regulations among employees do not understand what is expected of them.

Causes Of Unsafe Conditions :

Lack of Proper Maintenance

The equipment when not properly maintained may go bad and thus cause breakdowns, for example broken machinery or worn-out safety features.

Poor Design of Workspace

A poorly designed workspace would lack adequate ventilation, sufficient exits, or lighting, to mention but a few factors.

Environmental Factors

Severe climatic conditions or exposure to certain chemicals expose individuals to several risks.

Inadequate Safety Protection

A lack of sufficient physical barriers, warning signs, or protective gear.

Organisational Neglect

Organizations that pay little attention to safety probably have more unsafe conditions from lacking procedures.

Interdependence Between Unsafe Act and Condition :

Unsafe conditions and acts are often interdependent factors in a cycle of hazard.

For example:

- An unsafe condition, a cluttered workspace for instance, may encourage the workman to take short cuts in order to avoid working his way around the obstacles presented, thus creating an unsafe act.

- An unsafe act, such as storing hazardous materials improperly, may lead to an unsafe condition when that material becomes dangerous to others.

This is a relationship that shows why condition and behavior should not be treated separately in minimizing the accident.

Unsafe Act and Unsafe Condition :

Strategies for Managing Unsafe Acts

1. Training and Education: Routine training in safety procedures and equipment operation and emergency responses decrease the number of hazardous acts.

2. Well-Defined Policies and Procedures: Clearly communicated safety expectations minimize the occurrence of hazardous behaviors.

3. Behavioral Monitoring : Supervision of the employee’s conduct is also a way for the employer to detect any hazardous behaviors and intervene on time.

4. Rewards for Safety : The institution of safety incentives promotes desirable safe behaviors.

5. Regular Safety Meetings : All these discussions about possible threats remind employees of safe actions and make them responsible and careful.

Strategies for Managing Unsafe Conditions

1. Scheduled Inspections : Time to time checking of equipment, construction of the workplace, and overall safety of the workplace will identify hazards.

2. Maintenance or Repairs : Making sure that all the equipment and infrastructure installed in the workplace are optimum helps prevent many unsafe working conditions.

3. Engineering Controls of Safety : Barriers, safety guards, and alarms can reduce the hazards of a place.

4. Design of Work Environment : Properly designed layout, proper lighting, and ventilation in a workplace can reduce the risks of environment.

5. Regulations Compliance : Standards developed by the safety authorities, like OSHA, ensure that unsafe conditions are kept to the minimum.

Examples to Explain Unsafe Act and Unsafe Condition :

Manufacturing Plant

Unsafe Act : Worker who does not wear the press machine safety goggles and a glove.

Unsafe Condition : A machine where all the guards are out exposing workers to possible body and limb injury.

Scaffolding

Unsafe act : The worker ignores holding the harness while getting hold of the scaffolding structure.

Condition in Unsafe Condition : Without placing the toe boards, the possible threat of falling tools strikes in the heads of the ones under it.

Chemical Plant

Unsafe Act : A technician fails to check air quality before entering a confined space.

Unsafe Condition : The ventilation system is malfunctioning, and there exists the potential accumulation of toxic air.

Safety Culture in Reducing Unsafe Act and Unsafe Condition :

A proactive safety culture would decrease unsafe acts and conditions. When the organizational culture has safety as its inherent norm, the employees and management take responsibility for a safe practice.

This also includes:

Safety Mindset

Encouraging workers to value safety over productivity and speed.

Incident Reporting

Employees should be able to report hazards and unsafe acts without any fear of reprimand.

Continual Improvement

Always review and update the safety protocol to make sure that it is current and valid.

Read More : Near Miss

Conclusion :

Two forms of risk exist in the workplace; they include unsafe acts and unsafe conditions. They are from different sources. Unsafe acts are behavioral deviations that increase the risk whereas unsafe conditions are environmental or physical hazards in themselves. Accidents that would help organizations identify differences in their prevention can ensure proper management of both action and environmental factors. By having a sound safety culture, training, and prevention, the chances of accidents being reduced drastically can make work environments safer for everyone.

Q&A :

1. What are unsafe acts and how do they differ from unsafe conditions?

Ans : Unsafe acts are individual behaviors that deviate from safety practices, increasing accident risk (e.g., not wearing PPE). Unsafe conditions are environmental or physical hazards, like poor lighting or broken equipment, existing regardless of individual actions.

2. Why are unsafe acts harder to predict than unsafe conditions?

Ans : Unsafe acts vary with human behavior, influenced by factors like time pressure or overconfidence, making them spontaneous. Unsafe conditions, however, are more predictable and identifiable through inspections.

3. What factors contribute to unsafe acts?

Ans : Lack of training, time pressure, complacency, poor leadership, and communication gaps can all lead to unsafe acts in the workplace.

4. How can organizations manage unsafe conditions?

A : Regular inspections, maintenance, engineering controls (e.g., safety guards), and OSHA compliance help organizations mitigate unsafe conditions.

5. How does a strong safety culture help reduce unsafe acts and conditions?

A : A proactive safety culture prioritizes safety, encouraging adherence to protocols and hazard reporting, reducing both unsafe acts and conditions through ongoing training and improvement.

Such beautiful writing this is. I appreciate your talent.

iso 14001 consultancy in Bangalore

iso 14001 certification in Bangalore